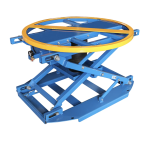

When it comes to material handling equipment, efficiency and safety are non-negotiable. The Xe nâng pallet cẩu CK20/CY20 from i-lift stands out as a game-changer for industries requiring seamless pallet handling without the hassle of slings or chains. But what makes this crane fork lifter a must-have for logistics and construction professionals? Let’s dive into its features, benefits, and why it’s dominating the material handling market.

Why Choose the CK20/CY20 Crane Pallet Fork Lifter?

1. No Slings or Chains Needed

Traditional pallet lifting methods often require additional rigging, which slows down operations. The CK20/CY20 eliminates this need, allowing the crane operator to remain in the cab while loading or unloading. This feature significantly enhances workplace efficiency and reduces manual labor risks.

2. Automatic & Manual Balancing Options

Các CK series (CK10, CK20, CK30, CK50) offers manual balancing, ideal for controlled, precise movements.

Các CY series (CY10, CY20, CY30, CY50) features automatic balancing, ensuring stability during lifting—perfect for uneven or dynamic loads.

This flexibility makes it a top choice for heavy-duty lifting in warehouses, construction sites, and shipping yards.

3. Adjustable Fork Width & Height

Whether you’re handling Euro pallets or custom-sized loads, the adjustable fork width (350-1000mm) và hook height (up to 2400mm) ensure compatibility with various pallet types. This adaptability reduces the need for multiple lifting attachments, saving both time and costs.

4. Heavy-Duty Load Capacity

With a Work Load Limit (WLL) ranging from 1000kg (2200 lbs) to 5000kg (11000 lbs), the CK20/CY20 can handle everything from light warehouse goods to industrial machinery. Its fork cross-section is reinforced for durability, preventing bending under stress.

Key Features at a Glance

| Mô hình | WLL (kg/lbs) | Fork Width (mm/in) | Hook Height (mm/in) | Net Weight (kg/lbs) |

|---|---|---|---|---|

| CK20 | 2000 (4400) | 400-900 (16-35.4) | 1640-2340 (64.6-92.1) | 200 (440) |

| CY20 | 2000 (4400) | 400-900 (16-35.4) | 1655-2355 (65.2-92.7) | 220 (484) |

Who Needs This Crane Fork Lifter?

Warehouse Managers – Streamline pallet handling without extra labor.

Construction Sites – Lift heavy materials safely with automatic balancing.

Shipping & Logistics – Speed up loading/unloading processes with fork adjustments.

Manufacturing Plants – Replace outdated lifting equipment with a more efficient solution.

Beyond the CK20/CY20: Explore More i-lift Equipment

As a leading crane fork manufacturer, i-lift offers a full range of lifting equipment, including:

Foldable shop cranes (SC series)

Electric hydraulic cranes (FEC450, HLC550E)

Adjustable pallet lifters (PL-A series)

Forklift attachments & drum handlers

Each product is backed by a 1-year warranty and expert after-sales service, ensuring long-term reliability.

Final Thoughts: Is the CK20/CY20 Worth It?

If you’re in the market for a versatile, high-capacity pallet lifter, the CK20/CY20 delivers unmatched efficiency. Its no-sling design, adjustable forks, and automatic balancing make it a standout in material handling technology.

Ready to upgrade your lifting process? Contact i-lift today for a quote—your next crane pallet fork lifter could be just an email away!

🚀 Pro Tip: For European buyers, we stock these fork lifters in France, ensuring fast delivery and lower shipping costs.